Mold manufacturing industry

If CNC machine tools, robots, wire cutting machines and CNC numerical control systems are the four iconic elements of metal processing automation, companies that can provide all four products mentioned above will undoubtedly become interpreters and solution suppliers of automatic chemical plants. For mold manufacturing, the core concept is high speed, high precision and high efficiency. For users, what they get is high quality, low price and high reliability, so as to improve profits and realize value.

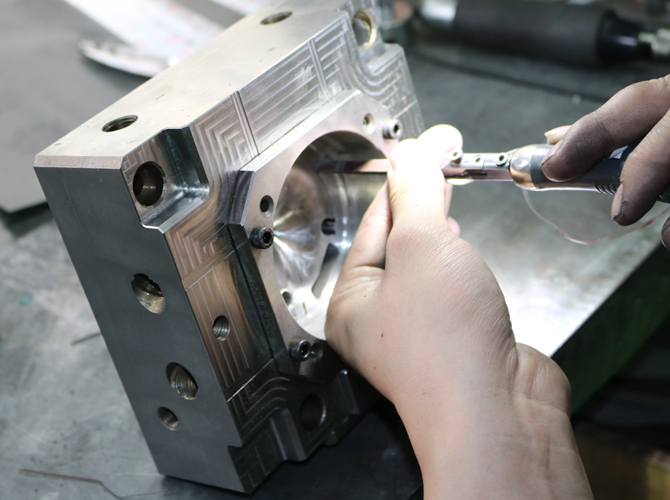

Robots in mold manufacturing industry

Intelligent robotics, networking and systematization are its full-automatic production concept. Around this concept, from casting to welding, forging to cutting, unloading to installation, cutting to polishing, we provide better products and solutions for automatic chemical plants no matter how complex the process is. Through the robot system, machining center and slow-moving wire cutting machine, the good matching and high reliability provide users with an unmanned production mode and realize an automated factory solution. Its modular structural design, flexible control system and prefabricated application package have become an indispensable good helper in the production of metal products.

Application of robot in mould manufacturing

The products are widely used in machining processes such as drilling, milling, cutting, bending, polishing and grinding. In addition, they can shorten the working cycle of welding, installation, inspection, loading and unloading and stamping processes and improve productivity. Even in the dirty and abominable production environment with much dust, heavy water and gas, high temperature, such as casting spraying, pouring, loading and unloading, deburring, milling and drilling, deburring, cleaning and other links, it can calmly deal with them and significantly improve the economic benefits of the production process. It has a compact structure and superior action performance, which can be perfectly integrated with the machining center in a narrow space. It uses the overall vision system to monitor in real time, quickly identify, correct, and accurately take and place, bringing an efficient and convenient solution for unmanned machining.